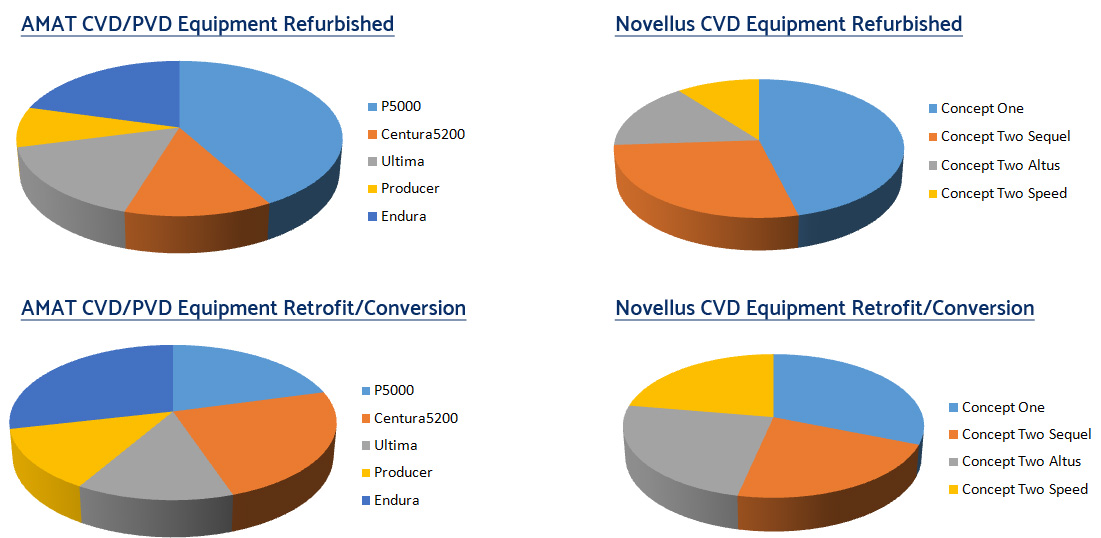

Equipment Remanufacturing

Current 200mm Equipment Market Situation

|

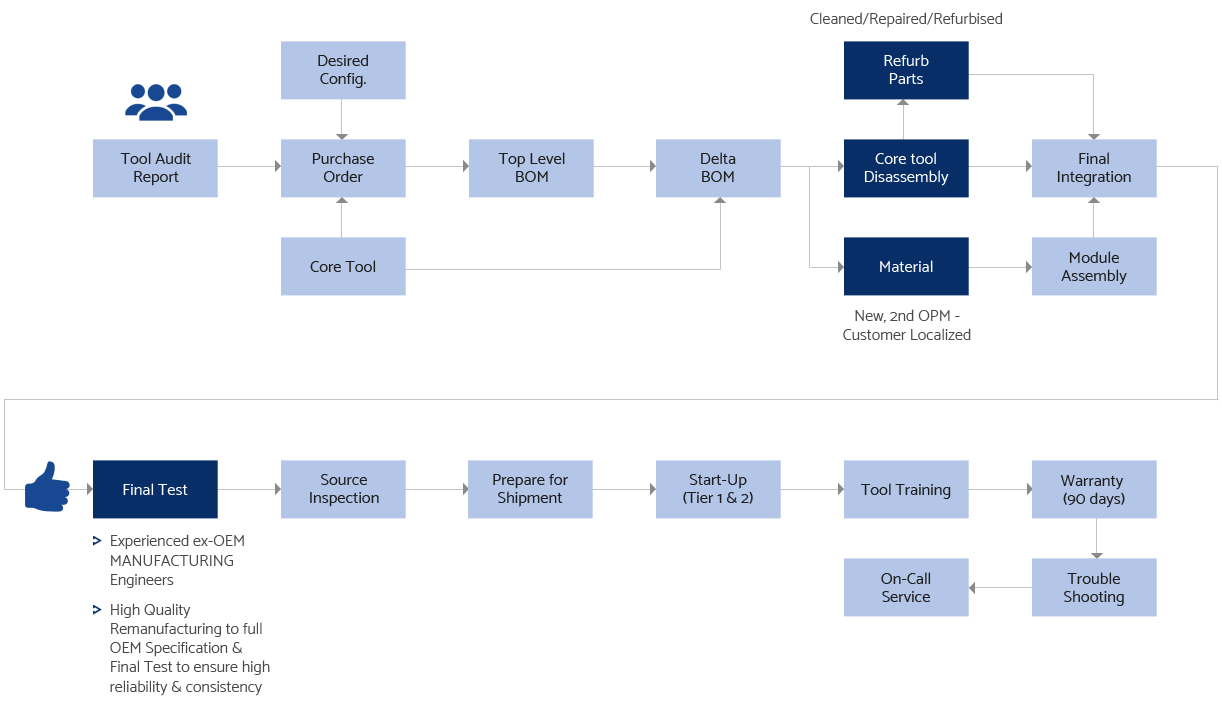

How to prepare Remanufactured Equipment

|